| The RWM application was deprecated with Appian 24.1. The application will no longer be updated or pre-installed for new Appian Cloud sites with Appian RPA enabled. RWM will be removed in a future release and we encourage customers to use the Operations Console to manage robots instead. |

After you get started with RWM, your business will need to know if the return on investment (ROI) is meeting your expectations. RWM has multiple metrics and visualizations to help demonstrate ROI and assist you with your automation strategy. This page discusses where to find this information in the solution to answer key questions such as:

- How much time and money are the automations saving per month?

- At what point will an automation break even on implementation costs?

- How do projected costs compare to actual costs once the automation is in production?

We've also described how each value is calculated, so you have full transparency into the data that help you make strategic automation decisions.

About ROICopy link to clipboard

At a very basic level, budgeting comes down to two aspects: the amount of money invested vs. the amount of money saved. In the context of automation, the amount of money invested encompasses things such as licensing, infrastructure overhead, and development time. Money saved is measured indirectly, such as reallocation of low value, rote tasks. When an employee doesn't have to spend their time or energy on these tasks, they can focus on tasks with higher impact for the business.

There are many other data points that might influence how you determine a budget. RWM provides this visibility into how much you invested in an automation and how much it saves you over its lifetime. Additionally, RWM collects data to produce an estimate to help you determine the value of future or proposed automations.

Automation savingsCopy link to clipboard

It can be tricky to measure and understand the savings an automation provides to your business. However, this is a key piece of understanding whether the automation is worth creating, maintaining, or expanding.

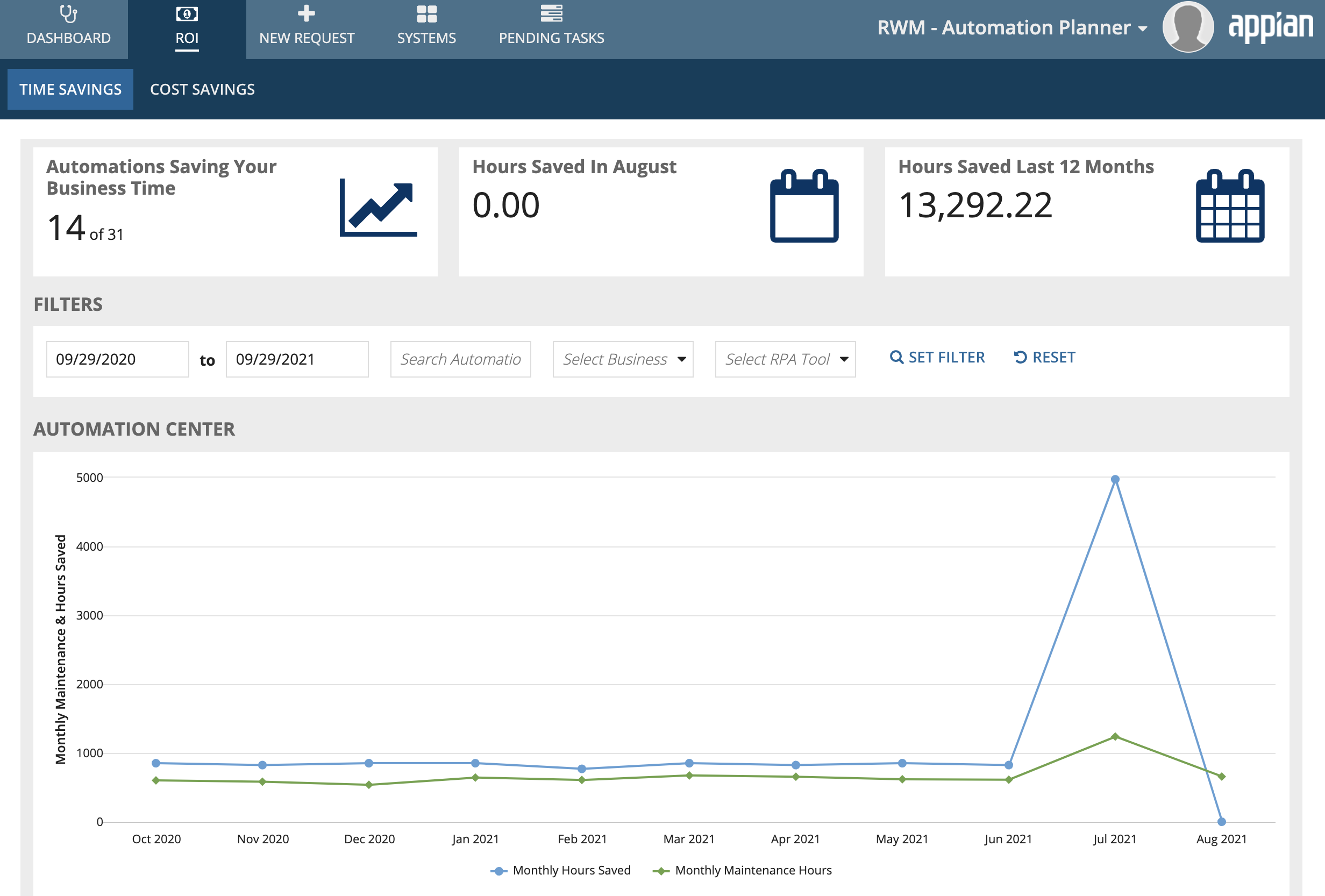

RWM helps you track automation savings in the ROI page of Automation Planner. On the Time Savings tab, you'll see key metrics summarized: automations saving time, total hours saved per month, and total hours saved in the past year.

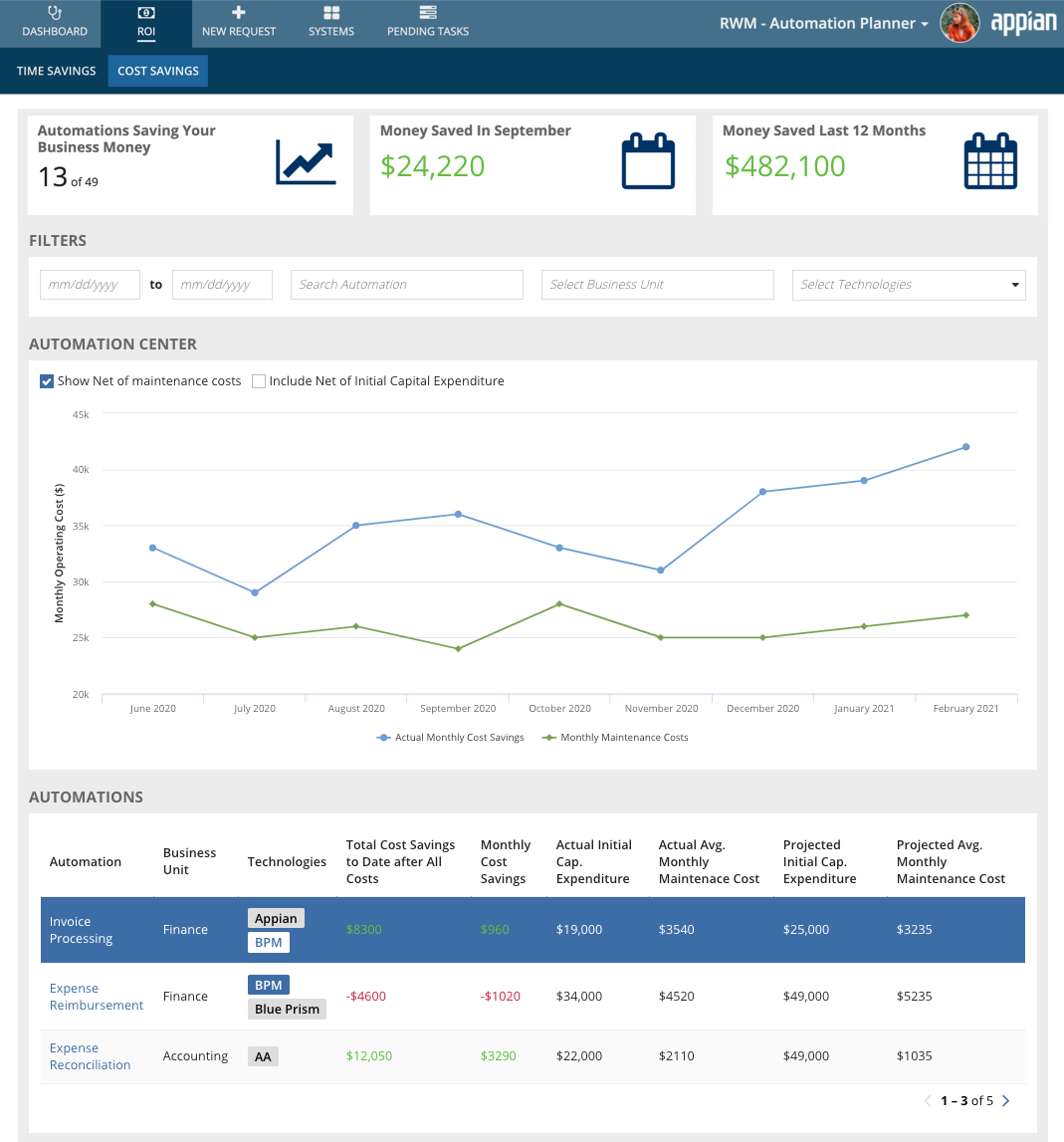

The Cost Savings tab shows you automations that save your business money, as well as the total savings for the past month and year.

Both tabs show detailed data for each automation in the Automations table. Use the Filters to refine the information shown in the table.

This information can help you determine which automations are performing well and which might not be proving their worth. These details can help you target automations for further investigation or additional resources. Knowing which automations save you the most money can also help inform decisions about which ones to maintain or expand. This information also helps you determine which one are underperforming, or are possibly no longer needed.

Projected savingsCopy link to clipboard

Projections aren't perfect, but as you develop more of them, you can learn lessons to make them more precise. If your projections show that an automation won't provide enough value, you can go back to the drawing board to examine the use case.

When individuals request new automations in RWM, they're asked to provide estimates of the time and money it will cost, as well as how long the automation will be used. RWM uses these estimates to project costs and savings, both in time and money. Reviewers can use this information to ask for additional details to understand the financial impact of an automation. Decision makers can review projected ROI to prioritize some proposed automations over others.

Tip: If you'd like to calculate and visualize the ROI for automations you already have in production, use the Add Existing Automations form on the Dashboard. This is best suited for businesses that used automations before adopting RWM to manage those automations. You'll enter all of the same information that's captured in the New Request form, but bypass the approval and implementation steps of the application.

Break-even pointsCopy link to clipboard

When you put an automation into production, you want to be sure it will provide value from day one. In the longer term, you may also want to know when the cumulative benefit you're getting from the automation starts to exceed the amount you've invested in its development. RWM uses automation metrics to show you this break-even point.

During the Budget Approval stage of a new Automation Request, the projected break-even point is shown to help give the user a sense of when the automation will switch from costing money to providing value. This date may help you determine the request's priority and whether this particular automation is a worthwhile investment at this time.

You'll see a similar graph on the ROI page. Click the automation in the list to view additional data and graphs. The Projected Break-Even chart shows the time when savings will be larger than costs, indicating the automation is worth the investment. The break-even point is where the Initial capital expenditure and maintenance costs and the Cost Savings lines intersect.

These ROI value calculations are based on data captured throughout the life of an automation. Users provide initial estimates of the time to maintain a new automation during the Automation Request phase. Automation Planner also prompts users to answer a monthly questionnaire to update this data or add new information, ensuring calculations are accurate and current.

Updating RPA costsCopy link to clipboard

The actual RPA costs may fluctuate over time and differ from what was projected before an automation went into production. These values can be updated through the Automation Planner Pending Tasks page, under the Update RPA Costs tab.

You can see a list of automations shown over time, with their respective last updated dates. Only the corresponding automation requestors, business CoE, technical CoE, and system admins can view these automations. Emails are also sent out to remind these users to update these automations. Updating consists of selecting an automation, and viewing the data month to month. This data is prepopulated, so the user can either confirm the data with no changes, or the user can update the values of one or more months. The page also displays which months have already been updated or confirmed with green check marks on the left hand column.

How ROI values are calculatedCopy link to clipboard

ROI is a complex set of metrics and rarely determined by one dimension. RWM provides multiple calculations to give you a complete picture of the costs and savings related to an automation. This section explains how these values are calculated.

Time Savings tabCopy link to clipboard

The calculations on the Time Savings tab focus on how much more quickly an automation completes executions than a human being would take to do the equivalent tasks. Some calculations also factor in the time it takes to create and maintain the automations.

Calculations that appear in the top-level graphs:

- Automations Saving Your Business Time: Number of automations with time savings greater than the time for implementation and maintenance.

- Hours Saved Last Month: Employee work hours saved by automations in production in the last full month.

- Hours Saved Last 12 Months: Employee work hours saved by automations in production in the last full 12 months.

Calculations that appear in columns of the Automations list:

- Total Hours Saved: Employee work hours saved over the entire life of the automation. Specifically, this is hours saved per RPA execution, multiplied by the number of successful executions since the automation has been in production.

- Average Hours Saved per Month: Total Hours Saved divided by the number of months the automation has been in production.

- Average RPA Executions per Month: Number of successful executions since the automation's go-live date, divided by the number of months the automation has been in production.

- Total Maintenance Hours: Number of developer hours of manual maintenance to keep the automation working as expected.

Additional calculations appear when you select an entry in the Automations in the table:

- Projected Cumulative Hours Saved: Projected number of hours the automation saves per month, multiplied by the number of months the automation has been in production.

- Actual Cumulative Hours Saved: Actual number of manual FTE hours the automation has saved since the automation has been in production.

- Projected Monthly Hours Saved: Estimated employee (FTE) work hours saved per RPA execution, multiplied by the projected number of executions per month. From this result, subtract the projected number of developer hours spent on maintenance.

- Actual Monthly Hours Saved: Estimated employee (FTE) work hours saved per RPA execution, multiplied by the actual number of successful executions per month. From this result, subtract the number of developer hours spent on maintenance.

Cost Savings tabCopy link to clipboard

The calculations on the Cost Savings tab focus on how much money automations save your business. Unless otherwise noted, an automation's cost savings can be calculated as the amount of money a full-time employee (FTE) would be paid to do the same work as the automation, minus the cost of setting up and maintaining the automation.

Calculations that appear in the top-level graphs:

- Automations Saving Your Business Money: Number of automations where total savings exceeds the total implementation and maintenance costs.

- Money Saved Last [Month]: Amount of money your automations saved the business last month, minus the costs of maintaining automations in production.

- Money Saved Last 12 Months: Amount of money your automations saved the business in the last 12 months, minus the costs of maintaining automations in production.

Calculations that appear in columns of the Automations list:

- Total Net Cost Savings: Employee (FTE) wages saved over the entire life of the automation, minus the costs of implementation and maintenance.

- Average Net Monthly Savings (Actual): Total savings on employee (FTE) wages, minus total maintenance cost, divided by the number of months in production.

- Initial Implementation Costs (Actual): Actual developer hours spent to create the automation, multiplied by their hourly rate, plus actual other costs for development.

- Average Monthly Maintenance Costs (Actual): Average of the monthly maintenance costs, such as developer costs and other costs related to automation maintenance. The monthly maintenance costs is derived from the monthly cost assessment task completed by the Business or Technical COE.

- Initial Implementation Costs (Projected): Projected developer hours spent to create the automation, multiplied by their hourly rate, plus projected other costs for development.

- Monthly Maintenance Costs (Projected): Projected monthly developer costs plus other costs related to automation maintenance.

Additional calculations appear when you select an entry in the Automations in the table:

- Projected Cumulative Savings: Projected gross amount the automation has saved since the automation has been in production.

- Actual Cumulative Savings: Gross amount the automation has saved since the automation has been in production.

- Actual Monthly Savings: Expected employee (FTE) work hours saved per RPA execution, multiplied by their hourly pay rate, multiplied by the actual number of successful executions per month.

- Monthly Total Maintenance Cost: Total of developer costs plus other costs for the month.

- Monthly Developer Cost: Number of developer hours spent on automation maintenance for the month, multiplied by their hourly pay rate. This metric is updated each month by the Business and Technical COE.

- Monthly Other Costs: Other licensing, infrastructure, or miscellaneous automation-related costs for the month. This metric is updated each month by the Business and Technical COE.